Our specialties

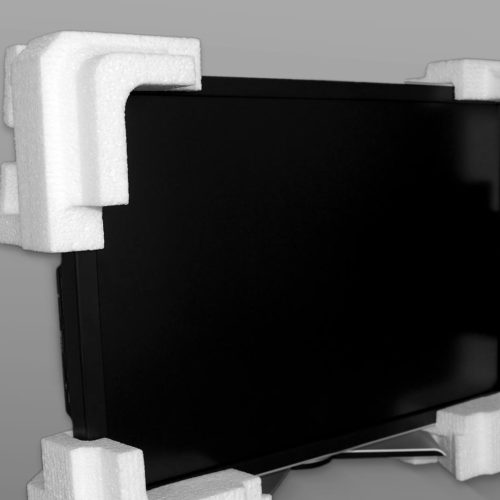

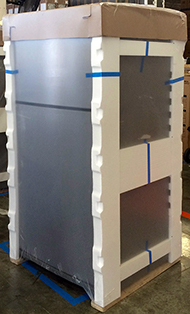

Regardless of the type of product you are shipping, Huntington has a protective packaging solution for you. We offer both off-the-shelf and custom designed solutions. We use a variety of materials and advanced resins to satisfy our customers’ demanding requirements for protective packaging. Our design engineers and packaging specialists leverage their expertise and knowledge to select the optimum materials to successfully engineer a complete solution.

For shipments that require crucial temperature assurance and protection, including pharma/biomedical, frozen foods, and perishables, Huntington offers a variety of cold chain packaging solutions incorporating the latest advanced materials that promote reuse and recycling. Huntington’s trademarked XDS™ Extended Duration Shipping containers are proven for 5-12 days.

As part of our portfolio of protective packaging solutions, Huntington was one of the first companies to fully implement the innovative Clear-View® stretch wrapping system with a number of major appliance manufacturers, resulting in reduced packaging and labor costs, improved logistics and lower product returns.

Utilized extensively in the automotive industry, Huntington’s light-weight energy management components provide exceptional strength and energy absorption to help manufacturer’s meet stringent efficiency, safety and emissions standards. These custom shapes and components are also found in child car seats, bicycle helmets and many other products.

Huntington offers a wide variety of custom engineered material handling and dunnage solutions including molded EPP foam and flexible cross-linked polyethylene XLPE foam. Huntington has in-house CNC waterjet cutting systems to ensure exceptional tolerances and reliability.

Huntington can custom fabricate EPS foam for a variety of industrial, commercial and residential building needs including insulation (GeoFoam), concrete forms and architectural foam shapes. The end result is lower cost and improved life of the design.

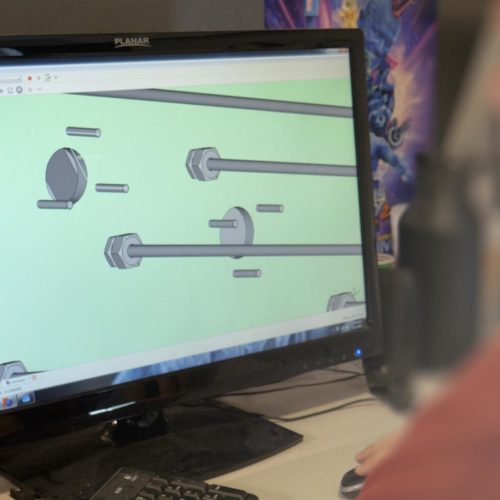

Huntington design and engineering services are led by some of the most experienced personnel in the industry. Capabilities include in-house 3D modeling, CNC prototyping and FEA Analysis. Huntington also offers a wide variety of comprehensive testing for any protective packaging solution (Shake, Incline, Stack, Compression, and Trans-Shipment testing), all designed to ASTM, ISTA or your customized specifications. We also offer simulation and qualification testing for cold chain shippers as well as complete custom engineering design services.

Keep it fresh!

Save on shipping costs with cutting-edge insulation for temperature control over extended periods.

Certifications

Huntington Solutions invests in the most advanced manufacturing technologies and quality management systems, with certifications to the latest Quality and Environmental standards.

IATF 16949

ISO 9001

ISO 14001

ISTA