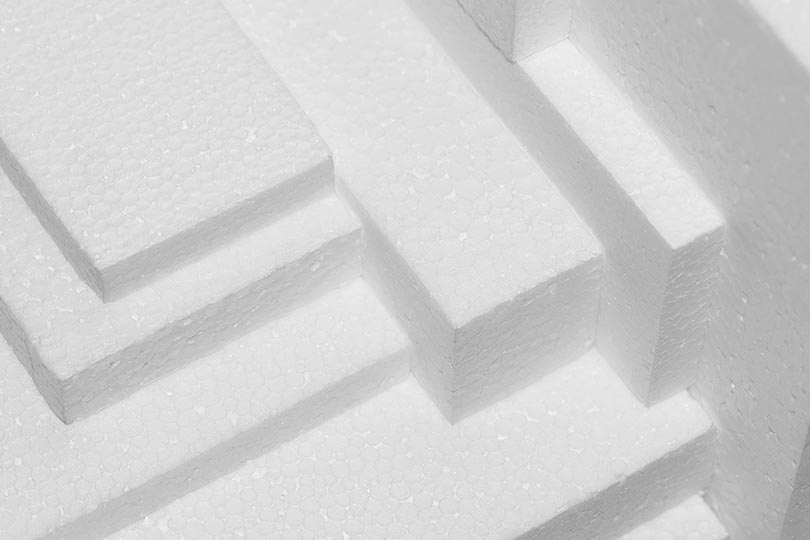

From packaging to bike helmets

With its unique characteristics, EPS can be adapted for countless functions critical to the 21st century economy.

Buoyant

98% air, EPS is ideal for marine applications such as flotation devices, surfboards etc.

Lightweight

EPS is easy to transport and can be set in place by hand or by lightweight construction equipment, making it ideal for:

- Packaging

- Concrete forms

- Form liners

- Loose fill

- Sign and letter molds

- Tilt up accents

- Tilt up insulation

- Void fillers

Versatile

EPS can be custom fabricated into almost any design, making it perfect for:

- Drainage foam

- Box liners

- Coolers

- Foam shapes

- Flotation

- Geofoam

- Theater and stadium seating

- Theatrical props and sets

- Vinyl siding backers

- Blocking, cribbing, and bracing

- Bottle and wine shippers

- Kitting, assembly, and packaging services

- Dividers and partitions

- Custom packaging, inserts, parts, and components

Durable

EPS is strong, stable, and absorbs energy. It is frequently used in:

- Below grade and perimeter insulation

- Sheet insulation

- Truck and RV wall panels

- Cant strips

- Laminated nail bases

- Precut saddles

- Square and tapered flute fillers

- Tapered panels

- Underlayment

- Bike helmets

- Car seats

- Automotive parts

Made of Expanded Polystyrene (EPS)

Many consumers refer to foam shippers and packaging as “Styrofoam coolers” or “Styrofoam packaging.” Although they may appear somewhat similar, our insulating containers and packaging are made from expanded polystyrene and specialty resins with different properties. Styrofoam is a trademark of Dow Chemical for its extruded polystyrene.